How are strides in artificial intelligence shaping the factories of the future?

The explosion of AI over the last 18 months has shaken up the world of work. From the automation of routine tasks to the enhancement of decision-making, white-collar jobs have been irretrievably changed by the technology.

But how about the manufacturing industry? What new jobs will be created by AI in manufacturing – and which ones will be rendered obsolete?

“AI won’t suddenly mean that there are less jobs available in manufacturing, it will simply change what job roles will entail,” says Kiran Ramasamy, Senior Recruitment Consultant (ML) at Harnham Group. “For example, using AI in automation may reduce manual workloads which will free up those workers to take on other tasks.”

“To take on these different types of tasks, workforces will likely need to be upskilled and supported in becoming more ‘data literate.’ This doesn’t mean that they will suddenly be expected to build AI in manufacturing systems – specialist candidates would still be required for this – but becoming more data literate, and understanding data processes to a basic level, will allow them to enable this more complex work to take place, for example knowing what information they need to provide to help to create the AI models.”

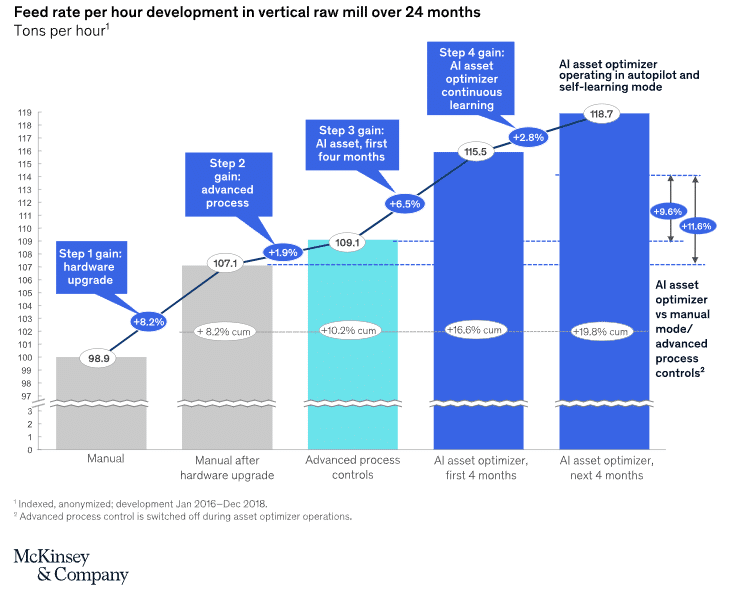

McKinsey research shows the effect of an AI asset optimiser on a cement company’s production

Top benefits of AI in the manufacturing industry

RPA (Robotic Process Automation): Eliminating the need for many manual tasks (Record maintenance, stock auditing, essentially any high-volume or repetitive task). RPA lowers the risk of human error with manual data input, alongside saving time and cost

Digital Twins: Creating a virtual model of a physical object is one of the main use cases of AI in manufacturing. For example, one of our clients has built an AI and Computer Vision model to scan construction sites for potential faults and issues potentially saving £millions and reducing construction site risk. This has been common in the automotive and aerospace industry for many years now (think simulating airflow in Formula 1 cars or spacecraft), but is now expanding to the wider manufacturing industry.

Supply Chain Management: AI systems able to manage large scale supply chains with millions of materials/orders to oversee. Reduces the risk of human error and a massive time/labour cost saving. Putting this information on the cloud (AWS being the most popular for this) allows all points of the supply chain to be able to view in real time where each component is, even helping to estimate delivery time/costs etc.

Looking to grow your AI team? Get in touch with us HERE.

How are these AI trends affecting manufacturing jobs?

RPA (Robotic Process Automation): “We have seen a rise in RPA Developer roles recently, and the need for a skillset of operating and maintaining this software,” says Kiran. “This is likely to increase the need for a more ‘Data-literate’ workforce in manufacturing.”

Digital Twins: “Again,” Kiran continues, “this will likely lead to more of the workforce needing to be ‘Data-literate’ to understand how their physical components can interact with smart sensors and how to interpret this data to conduct further simulations and anticipate any potential issues.”

Supply Chain Management: “With supply chains becoming even more complicated in recent years due to Brexit/Covid, jobs will shift from a practical hands on supply chain workforce to those who can help explain, visualise and interpret these AI findings to business stakeholders,” Kiran concludes.

Top manufacturing companies using AI

Siemens: Siemens is well-known for integrating AI in manufacturing processes, especially for predictive maintenance, process optimisation, and energy efficiency. Their use of AI in digital twins technology to simulate, predict, and optimize the product and production processes before the actual physical processes are built is particularly noteworthy.

General Electric (GE): GE leverages AI in its manufacturing processes to enhance efficiency, reduce downtime, and improve predictive maintenance through its Predix platform, which offers a wide range of industrial IoT services.

Toyota: As a pioneer in applying AI in manufacturing, Toyota uses AI to improve its production lines, enhance quality control, and for the development of autonomous vehicles. Toyota’s AI efforts also extend to robotics aimed at assisting people in their homes and workplaces.

Bosch: Bosch employs AI in its manufacturing operations to improve product quality and efficiency. The company uses AI to analyze data from machines and sensors to predict equipment failures and to optimize manufacturing processes.

Intel: Intel uses AI in its manufacturing processes to inspect and verify the quality of its semiconductor chips. The company’s AI algorithms can detect anomalies and defects at a scale and precision that were not possible before, ensuring higher quality products.

Follow us on LinkedIn

Check out The Data and AI Podcast

Looking to grow your data team or AI team? Contact us